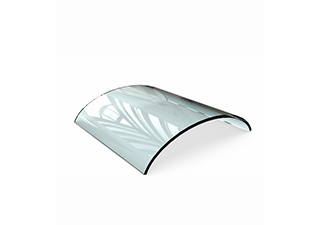

What's great about today's innovation is that it allows us to press the recognized limitations right into interesting, unknown territory. We can introduce, study and also develop genuinely life-altering designs. This is what we are beginning to see in the form of contours as well as shapes in the field of glass architecture.

And as the most up to date, architectural layout fads suggest, the world is ready for curved glass. We're willing to consist of curved as well as curved glass along with even more ingenious forms in our structures.

Why curved glass?

The aesthetic charm is not the only facet driving designers throughout the globe towards the curved glass. Remarkably sufficient, curved glass is likewise highly effective when made use of in architectural glazing applications.

Not just that, the curving actually makes it extremely fill immune. When made use of properly, arching likewise reduces deflections. In practice, curved glass solutions are excellent in architectural applications. And also when designed well, they can reduce the use of various other structure products.

Is today's technology an obstacle or opportunity?

Some could think about today's handling technology to be a traffic jam for economical curved glass manufacturing. That could be real for some companies. But for us, it's an opportunity. Below, I'll sum up the primary glass flexing innovations made use of today.

That claimed I wish this blog post will provide you a brand-new perspective on what can be attained today. And for added value, I'll likewise enlighten you about the opportunities of tomorrow. Let's reach it!

The glass flexing modern technologies today are:

·Flexing and also toughening up

·Warm bending

·Cold flexing

·Laminated bending

Let's take a much deeper consider these modern technologies.

Bending and also tempering

Many typically in the flexing as well as a tempering process, the glass is first heated up to over 630 ° C. When warmed, the glass is then bent to its target distance in the bending terminal.

Although bending systems most typically generate cylindrical types, it's not unusual to produce small bi-directional bending by angling the glass throughout the procedure.

The glass can be turned right into the direction in which the glass streams, which is referred to as lengthwise bending. It can likewise be curved crosswise throughout the glass circulation, which is called crosswise bending.

As high quality is always an essential factor to consider, lengthwise bending offers a far better quality cause regards to optical top quality.

Hot bending

In hot flexing, the curved glass manufacturer utilizes molds, which permit the glass to take on the preferred kind. The glass, in addition to the mold and mildew, is then heated up to 580-- 600 ° C.

Bending can be solely based upon gravity. Additionally, the glass bending procedure can be aided in which a mechanical bending press forces the glass into a target shape. The shape is that slowly cooled to stay clear of any type of residual tension in the glass.