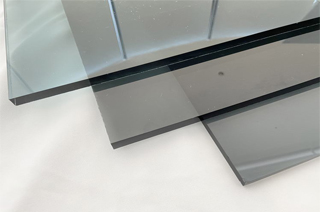

When it comes to glass, it is often difficult to decide which type of glass is the best choice for your storefront or home construction. The most common type of glass is laminated glass, which is also not very safe. Today we are going to discuss a different and more secure kind of glass, toughened or tempered glass, and its difference.

What is tempered glass?

Tempered glass is also called toughened glass, so you have noticed that these two names are usually used for the same kind of glass. This kind of glass is usually much stronger than ordinary glass, up to 5 times. Its production process is to heat ordinary glass at a very high temperature (over 600ºC) and then quickly cool it down. This process creates a harder glass surface that is 500% higher in heat and impact resistance than ordinary glass.

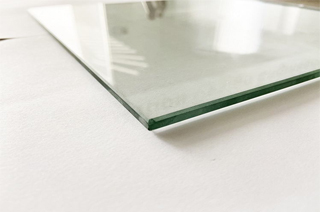

By making a stronger and tougher type of glass, you can make huge improvements in the durability and strength of the glass structure. Due to this stronger and tougher surface, this type of glass must be shaped and cut before the tempering process. If you try to cut after the toughening process, it is likely to break into thousands of pieces, but it is 100% customizable according to customer needs.

Due to its heat treatment, tempered glass provides thermal resistance, is also waterproof, not to mention thermal efficiency, and will help you save money in your business.

This kind of glass is more for safety reasons, because even if it is difficult to break, when it is broken, it will break into many small pieces, reducing the chance of causing danger and injury to people.

Where are toughened glass and tempered glass used?

Due to its super creative process, tempered glass can be used in a variety of different architectural applications. It all depends on the customer! Whether you choose to use it in your home bathroom or in front of your glass shop, tempered glass is your best choice!

It can also have different types of uses, such as countertops, desktops, greenhouses, shower screens, shelves, kitchen splashbacks, internal partition walls, store facades, windows, etc.

The benefits of using tempered safety glass in the store are as follows:

Increased strength, flexibility, and high-temperature resistance.

It is 5 times stronger than ordinary glass, which means it is safer for the storefront.

It is safer than ordinary glass because when it is broken, it will shatter into smaller pieces of glass.

Thermal efficiency compared with ordinary glass.

We are toughened safety glass supplier. If you are interested in our products, please feel free to contact us.